Penny Farthing Restoration

For as far back as I can recall, my family has been in the possession of a 1950's custom-built penny-farthing. Designed and built by my grandfather, as a gift to his children it was once the centre of great enjoyment and even featured in the local newspaper. It has since fallen into disrepair due to several decades of neglect and weather exposure, resulting in extensive surface rust, pitting, tyre decay, faded paint, insect nests, rust stuck bearings, and cracked timber handles. This project appeared to be too challenging to tackle, until early 2020 when I found myself with enough spare time to properly undertake the restoration.

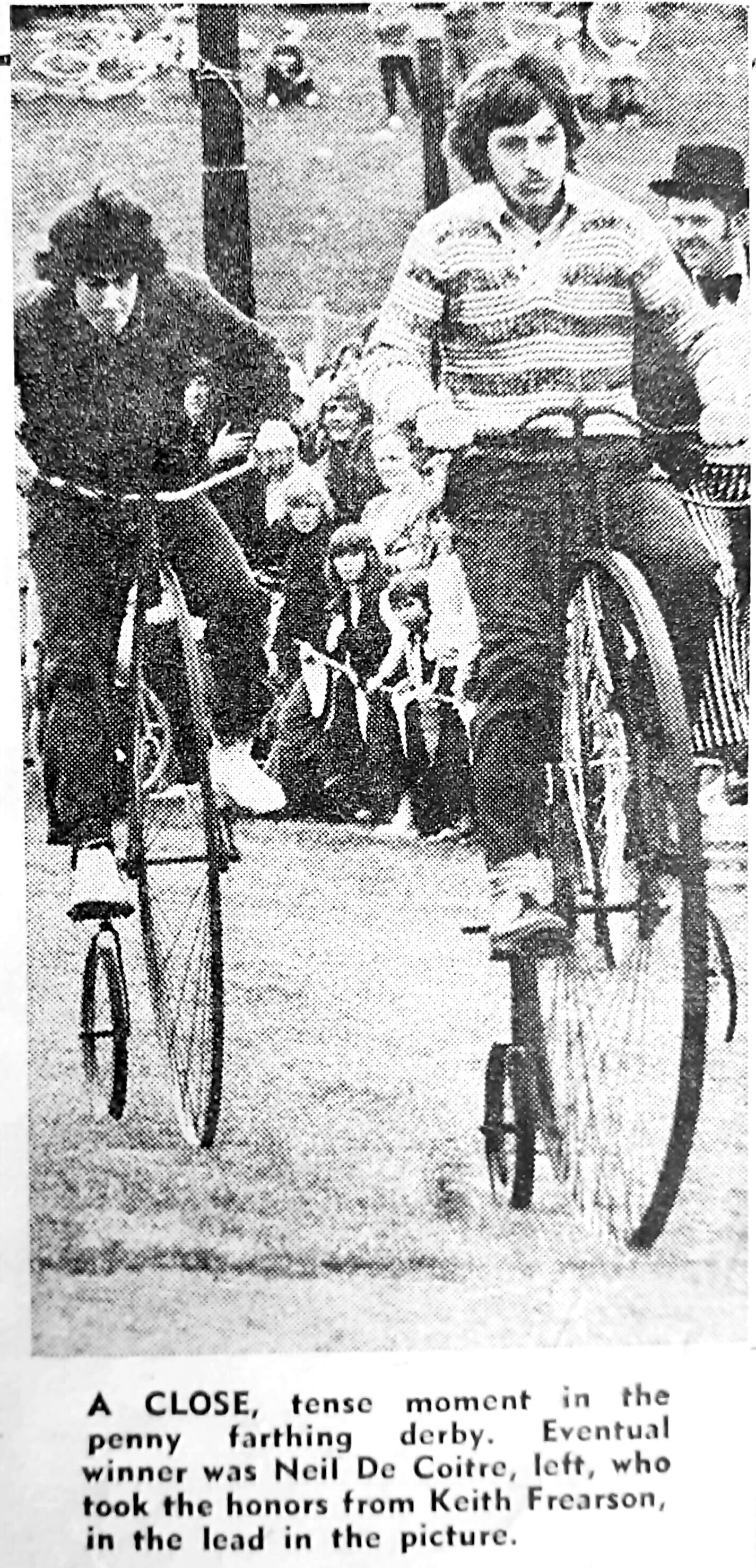

Clipping from the Sun Newspaper, September 1, 1975. Sidney Myre Music Bowl

After a close inspection, I was surprised to find the bike to still be mechanically operational and intact despite almost 40 years of neglect. To help document this restoration project, the handlebars, steel frame and wheels were broken down into 3 manageable segments to be independently disassembled and cleaned through various restoration techniques and processes.

Tasmanian Oak

Wooden Handle

After removing the fork and disassembling the handlebars, I gave the entire surface a preliminary clean with a wire brush followed by a heavy-duty wire wheel attachment on my angle grinder. This resulted in a nice matte finish on the blackened steel which still showed evidence of some pitting and corrosion. To protect the new surface from any further erosion, several coatings of rust guard were applied followed by 3 layers of matte black spray paint to honour the original colour of the bike.

The original timber handles had lost all-natural colour and had decayed to the core from a mixture of water damage and sun exposure, resulting in a loose fit and a coarse surface. As a replacement material, I chose repurposed Tasmanian Oak floorboards due to their natural hardness, resiliency to weather exposure and appealing warm straw colour. Cut down from an 80 x 80 x 140mm block, these handle blanks were chamfered on the table saw and then turned to an approximation of the original handle profile on the lathe. The centre was drilled out on a pedestal drill, finished with a progression of 40, 120, 600 and 800 grit sandpaper and coated in boiled linseed oil and beeswax. Whilst this combination darkened the timber more than I expected, this finish resulted in a stark contrast in material and colour which emphasises the age and era of the bike.

Molybdenum

Steel Frame

As my grandfather was an aircraft pilot and a fitter and turner during the second world war, he had the technical know-how and resources to manufacture the frame of the penny-farthing out of aircraft grade molybdenum steel. Possessing a high resistance to corrosion and heat whilst holding great tensile strength, the moly steel frame held its form and exhibited no rust or corrosion damage at all after 40+ years.

Commonly used in the fabrication of fuselages of aeroplanes since the 1920s, the steel had to be incrementally rolled through a manual tube rolling mill to achieve the desired form. The handle fitting plate, rear tyre fork and seat mounting bracket all appear to be brazing as seen in the golden coloured joints. After hitting the frame with a wire brush, I applied several layers of rust guard followed by 3 coats of black spray paint.

As the original Dunlop bike seat had deteriorated beyond repair, I purchased a genuine leather, spring-suspended vintage seat to match the era of the bicycle and colour palate. As the standard fitting brackets of bike seats haven't changed much over the last few decades, I was able to mount the seat directly onto the original bracket without any modification.

Custom Built

52” Wheel

Similar to the frame, the 52-inch front wheel appeared to be fabricated by hand with identifying weld marks around the rim as well as remnants of automotive body filler and black paint. This wheel was made from a standard steel alloy and was covered in rust spots, a few holes, and a general poor surface condition. The spokes and corners were difficult to access with the wire wheel so I constructed a large custom water tank to electrically remove the surface detritus. This process is known as electrolysis and uses an electrical charge from a car battery charger to stimulate the exchange of ions between the expendable steel anodes and the workpiece. This exchange disrupts the entire surface of the wheel and separates surface rust and paint from the steel. I left the wheel fully submerged for 24 hours in a bi-card and water solution, and returned to find the water surface thick with rusty foam and the wheel blackened in colour.

The process was far more extensive and thorough than I could have ever achieved by hand, and post-processing with a wire brush removed all excess paint found on the spokes and rim. Just like the rest of the frame, three coats of rust guard were then applied to the newly exposed steel, followed by two coats of silver paint. I chose silver to highlight the spokes and rim against the black tyre and frame, and create a sharper appearance, more modern look.

After several failed attempts in sourcing specialty penny-farthing tyre rubber, we finally found and purchased a 6.5m length of 1" hollow tubing from a penny-farthing supplier in the U.S. While the tyre as approximately 10mm too narrow to fill the channel of the 52" front wheel, we overcame this by gluing two strips of hard plastic tubing into the corners, which allowed the tyre to self-centre when strapped onto the wheel.The tyre itself is 10% longer than the perimeter of the wheel, to allow for rubber expansion and features an internal wire core that is fixed under tension to hold the rubber onto the wheel.

Attached through a rigging system using a chain hoist and a custom fitting jig, the tension we applied to the wire core using the custom spacing bracket allowed us to maintain a gap in the rubber tyre whilst working on the connection. We then twisted the wheel 180° to create a positive wire joint and fed the snipped ends into the rubber tubing. The jig was then removed allowing the compressed tyre to expand naturally filling the gap and hide the seam, resulting in a clean professional Finnish.

Overall I am very pleased with the outcome of this project as the entire bicycle has been restored to full functionality whilst maintaining the original colour scheme and aesthetics of a 20th-century penny-farthing. During this restoration, I was able to refine several fabrication and restoration techniques including steel cleaning and precision woodturning. Despite a few minor delays, I was able to complete this restoration within a month and under budget with the largest cost coming from the tyre purchase. This project was completed with a newfound respect for mid-century manufacturing techniques and resourceful ingenuity.